India tech news today is ablaze with stories of rapid innovation. From a surge in AI investments to new chip-making plants and record startup funding, India’s tech ecosystem is booming. In the past year, Indian AI startups raised $560 million in 2024 – 25% more than 2023. Government programs like the new IndiaAI Mission (₹10,300 crore over five years) are fueling this growth with major compute infrastructure and policies. Meanwhile, the country’s semiconductor industry is ramping up: the Union Cabinet approved several fab projects totalling over ₹1.6 trillion ($18.23B) by mid-2025. Startup funding is rebounding too: Indian tech startups drew $4.95B in H1 2025 across 410 deals. In short, India’s role in global innovation is expanding – the nation is ranked 39th in the 2024 Global Innovation Index and is now among the top contributors to worldwide patent filings mondaq.com.

This article examines today’s key tech trends – AI in India, chip manufacturing, venture funding, and innovation achievements – citing recent data and examples. You’ll learn how India’s initiatives and investments are driving tech leadership, what the big startup stories are, and why analysts say India is poised to be a global innovation powerhouse.

Alt: A person writing notes with a laptop and smartphone on a desk, illustrating a dynamic startup workspace. Indian startups thrive in vibrant, hands-on work environments. As one example, India’s startup ecosystem secured $4.95 billion across 410 deals in the first half of 2025 economictimes.indiatimes.com. This funding is helping founders develop cutting-edge products in fintech, edtech, healthtech and more. The first paragraph above sets the stage for “India tech news today,” highlighting the explosive growth in AI investments, chipmaking plans, and startup funding. Each subsequent section dives into these trends in detail.

AI in India: Explosive Growth and Investments

Artificial Intelligence (AI) is at the forefront of India’s tech wave. Indian startups and companies are adopting AI aggressively, and global investors have taken notice. In 2024 alone, India’s AI startups raised $560 million – a 1.25× jump from 2023. Enterprise AI deals are surging, particularly in generative AI and deeptech. For instance, generative AI startups raised $524 million in the first 7 months of 2025 – the highest five-year total on record economictimes.indiatimes.com. Another report found that by August 2025 India’s AI startups had already brought in $665 million (a 46% year-over-year rise) across 109 deals.

This funding is spread across various AI domains: natural language processing, computer vision, machine learning for healthcare, finance, and more. A Bessemer Venture Partners report notes that about 25% of venture dollars in 2024 went into AI-focused software companies. Moreover, 79% of Indian firms plan to increase AI budgets in 2024 – the highest rate globally indiaai.gov.in. In other words, businesses from startups to conglomerates see AI as a strategic priority.

Indian AI innovation is not just about funding – it’s also about infrastructure. The government’s 2024 IndiaAI Mission earmarked ₹10,300 crore (about $1.25B) over five years to build GPU clusters and support compute services. For example, thousands of high-end GPUs have been procured and pooled into a national AI supercloud, giving startups affordable access to cutting-edge processing power. The IndiaAI Mission also includes creating open datasets and foundational models (“BharatGen”, “Sarvam-1”) tailored to Indian languages and needs. These initiatives aim to ensure that “India’s AI startup ecosystem is on the brink of explosive growth”, as one industry leader put it.

Key supporting points for AI in India include:

- Robust funding trends: Indian AI startups raised hundreds of millions in 2024–25, driving record-breaking deals. Major funding rounds in AI and deeptech continue to be announced weekly.

- Enterprise adoption: 79% of Indian companies (the highest globally) will expand AI projects in 2024. Sectors like fintech, telecom, and retail are embedding AI into products and operations.

- Government backing: Programmes such as IndiaAI and Digital India are actively investing in AI compute, skills development, and ethics frameworks.

- AI for societal needs: Initiatives leverage AI in healthcare, agriculture, education and public services. For example, AI-based analytics were used for crowd management during Kumbh Mela 2025, and AI is being integrated with Aadhaar (digital ID) for improved governance.

These trends show that AI in India is not a buzzword but a core strategy. Analysts expect continued growth: projections foresee India’s AI-driven software market reaching tens of billions in ARR by 2030, boosted by the current investments. As India’s AI ecosystem scales, it’s also looking outward: US and Indian VCs launched a $1+ billion India Deep Tech Investment Alliance (IDTA) in Sep 2025 to support AI, quantum, space tech and more thequantuminsider.com.

Semiconductor Industry India: Building the Chip Ecosystem

A key theme in India tech news today is the long-awaited rise of domestic semiconductor manufacturing. Historically, India imported most of its chips. Now multiple projects are changing that. The government’s India Semiconductor Mission (ISM) and associated PLI (Production-Linked Incentive) scheme have mobilized nearly ₹76,000 crore ($9B) for chip manufacturing and design. Of this PLI budget, roughly ₹65,000 crore has already been committed to approved projects. In late August 2025, Prime Minister Modi announced that India would roll out its first domestically produced chip by end-2025 (using 28–90 nm technology) and that six chip fabs are under development.

Recent news highlights include:

- New fabs approved: In May 2025, the Indian cabinet approved an HCL-Foxconn joint venture fab near Jewar Airport, Uttar Pradesh (37.06B rupees, $435M) producing display driver chips. This is the sixth plant approved under ISM. Other major projects underway are an $11B chip fabrication unit by Tata Group and a $2.7B chip packaging (OSAT) facility by Micron. On August 12, 2025, four more manufacturing projects were sanctioned, bringing the total to 10 approved projects with investments of ~₹1.6 trillion. These include India’s first silicon carbide (SiC) compound semiconductor fab and advanced glass-based packaging lines.

- Infrastructure and partnerships: At SEMICON India 2025 (Sept 2025), officials announced launch of an end-to-end OSAT pilot line in Sanand, Gujarat. India’s Design-Linked Incentive (DLI) scheme has already backed 23 chip design projects. Global firms are partnering: Tata Electronics signed MoUs with Merck and India’s CDAC to jointly develop advanced packaging and chip design ecosystems.

- Government targets: Under ISM, the govt has allocated ~97% of a ₹65,000 crore semiconductor incentive fund india-briefing.com. Plans also include modernizing the Mohali Semiconductor Laboratory and design incentives to build domestic IP. Officials project that by 2030, one million skilled semiconductor workers will be needed.

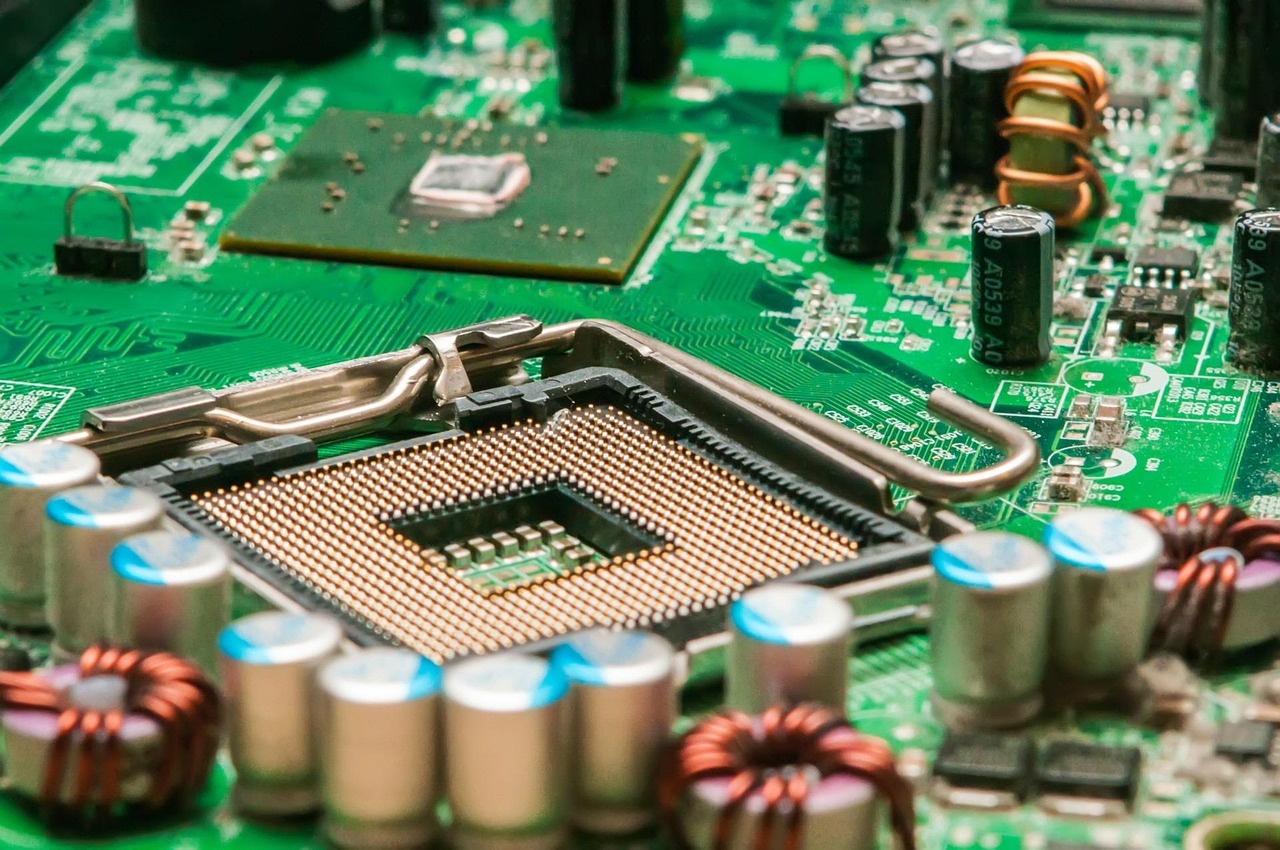

Alt: A close-up of a green circuit board with microchips and solder points. The government’s PLI scheme (₹76,000 crore) and industry partnerships are putting India on the global chip map. These initiatives are already attracting foreign investment: e.g., Micron was approved to build a $1.51B chip facility in Gujarat, and foreign OEMs like Infineon are launching India-oriented production lines.

Today’s news also notes challenges. For instance, a $19.5B chip JV between Vedanta and Foxconn fell through in 2023, and Adani paused a planned $10B chip venture. Still, industry analysts emphasize that strong policy support has “given shape to [India’s] dream” of self-reliance in chips. Indeed, Semicon India 2025 concluded with the formation of a $1B India Deep-Tech Investment Alliance (IDTA) to mobilize private capital for frontier tech (including semiconductors) economictimes.indiatimes.com.

Key takeaways for India’s semiconductor drive:

- Massive investments: Over $18B approved in projects (Oct 2025).

- PLI incentives: ₹76,000 crore program, with ₹65,000 cr committed.

- Domestic chip goals: First ‘Make-in-India’ chip by 2025, focusing on automotive, power, telecom use-cases.

- Global partnerships: MoUs with firms like Merck, Infineon, MNCs, to develop local value chain.

- Workforce focus: Plans for skilling ~1 million semiconductor workers by 2030.

This transformation of the semiconductor industry in India is critical: chips power everything from phones to defense. As one official noted, India is no longer just a consumer of electronics but is becoming a “creator” of chips. The latest announcements reinforce that message: multi-billion-dollar fabs and design hubs are either ready or coming soon, laying the foundation for long-term growth.

Trending Startup News and Funding

India’s startup ecosystem continues to make headlines. Despite a global VC slowdown, funding levels in India show signs of recovery. In H1 2025, Indian startups raised $4.95 billion across 410 deals – up 9% from H1 2024. This rebound is driven by strong interest in certain sectors: e-commerce startups attracted ~$1.3B, fintech ~$1.0B, and deeptech and enterprise SaaS pulled significant capital. Notable raises in 2025 include ecommerce giant Meesho ($270M), stock-trading platform Groww ($200M), and healthcare platform PB Fintech ($218M).

Alt: A humanoid AI robot figure against a dark background. Deep tech and AI startups are also hot spots. In early 2025, as mentioned above, AI startups raised $524–665M in just seven months economictimes.indiatimes.com. Investors like Tiger Global, Accel, and Premji Invest (Azim Premji’s firm) are leading rounds, reflecting confidence in India’s tech talent.

Overall funding in India is still below the 2022 peak ($16.2B in H1 2022) economictimes.indiatimes.com, but experts note this normalization is healthy. VCs emphasize profitability and unit economics over unchecked growth. Many later-stage companies (soonicorns and unicorns) are now pursuing public listings or high-value private rounds – e.g., shares of several unicorns saw new growth rounds recently. As of mid-2025, India has over 122 unicorns (startups valued >$1B), collectively worth $363B cgichicago.gov.in.

Key points in the startup scene:

- Unicorn boom: 122 Indian unicorns by May 2025, with $115B raised total cgichicago.gov.in. India is now third in the world (after US/China) for fintech unicorns, and leads in numbers of healthtech and edtech billion-dollar startups in Asia.

- Sector highlights: E-commerce (Meesho, Swiggy, etc.), fintech (PhonePe, Razorpay), SaaS, edtech (Byju’s remains India’s largest unicorn), and emerging areas like agritech, climate tech. For example, India’s burgeoning climate-tech startups are gaining foreign VC interest due to India’s focus on sustainability.

- Government support: Programs like Startup India and funds from SIDBI/NITI Aayog continue to assist early-stage ventures. Grant schemes and regulatory easing (e.g., faster GST refunds, digital KYC) help startups scale.

- M&A and IPOs: Several startups are eyeing exits. In late 2025, media reports show Indian startups filing for IPO (DRHP) such as Shadowfax, PhysicsWallah, and even fintech firms, indicating maturation of the ecosystem economictimes.indiatimes.com.

- Global linkages: Many top Indian startups have global founders, or are backed by international investors. Initiatives like India Global Innovation Connect (IGIC) in 2024 and partnerships (IDTA) attract US, Europe, and Middle East capital to Indian deeptech and AI ventures.

In sum, trending startup news in India centers on escalating deal sizes in core sectors and the growth of deeptech. Indian founders are increasingly tech-savvy and are leveraging local engineering talent. The funding environment has shifted to focus on sustainability – startups with strong business models are “oversubscribed” by investors. This healthier approach, combined with a large and growing domestic market, suggests India’s startup scene will continue to produce new innovation stories.

Digital Infrastructure and Tech Ecosystem

India’s tech headlines aren’t just about private firms. Public digital infrastructure and policies also feature prominently. India has built the world’s largest biometric ID system (Aadhaar) and digital payment network (UPI). In news, this year India’s Public Digital Infrastructure (DPI) initiatives expanded further. For example, the AI-driven features are being embedded in DPI: the government aims to enhance Aadhaar and UPI with AI tools for fraud detection and personalized services.

Other technology developments:

- 5G rollout: Telecom operators have begun 5G services across India. By late 2025, millions of new 5G-capable phones were activated, enabling faster mobile internet and IoT applications. Government auctions and private network bids (e.g. for utilities and railways) have raised record sums, signaling strong private sector involvement.

- Data economy: India released policy drafts (e.g., Digital India Act, Data Protection Bill) to regulate data flows and promote data localization. The government’s Open Data initiative is expanding public datasets (geospatial, health) to spur innovation by startups and researchers.

- Green tech: Startups in clean energy, battery storage, and electric vehicles are trending. India announced support schemes for renewable energy manufacturing and battery recycling, attracting climate-tech entrepreneurs. For instance, investment alliances highlighted solar and battery innovations at recent climate summits.

- Global partnerships: Initiatives like the G20 Digital Economy working group and bilateral agreements (e.g., U.S.-India TRUST Pact, Australia-India tech bridge) are framing India as a key player in global tech governance.

The Digital India campaign and Make-in-India vision continue to overlap with these trends, aiming to turn India into a digital powerhouse. These efforts create a virtuous cycle: strong infrastructure (broadband, data centers, payment rails) enables startups to innovate rapidly, which in turn spurs further tech growth.

India’s Role in Global Innovation

India’s rapid tech progress is reflected in global metrics. The Global Innovation Index (GII) 2024 ranks India 39th among 133 economies – a big leap from 81st in 2015. In fact, India leads in its income group (Lower middle-income) and in its region (Central/South Asia). The rise is driven by strong showings in digitalization, intellectual property, and creative outputs.

In intellectual property, India is increasingly a top filer. The 2024 WIPO report shows India is 6th in the world for patent applications (64,480 filings in 2023). Notably, for the first time in 2023 more than half of patent filings were by Indian residents (55.2%), highlighting growing domestic R&D. Industrial design registrations also surged by 36% in 2023. These trends underscore India’s shift from a patent importer to a creator of technology.

India’s innovation ecosystem is supported by government schemes (e.g., Startup India, Atma Nirbhar Bharat, National AI strategy) and educational reforms (new IITs, IISC expansions). The number of tech incubators and science clusters (e.g., Bengaluru, Hyderabad, Pune, Chennai) is rising. Global tech giants are also investing in India’s talent: R&D centers of Google, Microsoft, Apple and many startups are active in India. In space and defense, ISRO and DRDO have partnered with startups for satellites and unmanned vehicles, adding to the innovation narrative.

In summary, readers will take away that India today is a rising tech hub. The country is no longer only a market for foreign tech; it is producing its own AI solutions, designing chips, and fostering global unicorns. With record-breaking funding rounds and major policy support, India’s innovation capacity is recognized worldwide static.pib.gov.in. The growth in patenting, startup valuations, and government R&D spending signal that India’s impact on global technology trends will continue growing.

Conclusion

India tech news today is filled with optimism. From AI in India to the blossoming semiconductor sector and a vibrant startup scene, the nation is charting a path to global tech leadership. In this article we saw that India’s AI startups have raised hundreds of millions in fresh funding and companies are planning to allocate even more budget to AI projects. We saw that semiconductor industry India is a key focus area, with billions of dollars in fab projects approved and a large government incentive scheme propelling local chip manufacturing. We reviewed how trending startup news shows a modest recovery in venture capital (nearly $5B in H1 2025) and an ever-growing herd of unicorns ($115B raised by 122 startups). Finally, we placed India’s advances in context of global innovation, noting top-10 rankings in IP filings and leaps in the Global Innovation Index mondaq.com.

In sum, readers of this article will gain a comprehensive update on India’s tech landscape: you’ll understand which areas are hot (AI, semiconductors, deeptech), how the ecosystem is evolving (funding trends, startups, government programs), and why India’s global innovation role is rising. This snapshot of India tech news today should help investors, entrepreneurs, and tech enthusiasts see where India stands – and why many say India is “in its moment” to drive the next wave of technology innovation.

FAQs

Q: What are the latest AI initiatives and investments in India?

A: India has launched a ₹10,300 crore National AI Mission (2024–29) to build GPU clusters, open datasets, and support AI research. In the private sector, Indian AI startups attracted $560 million in 2024, up 25% from 2023. Large funds and alliances (e.g. the India Deep-Tech Investment Alliance committing $1B to AI and deeptech) are fueling this growth. Surveys show about 79% of Indian companies plan to increase AI budgets in 2024, indicating strong adoption across industries.

Q: How is the semiconductor industry growing in India?

A: India is rapidly expanding its chip-making ecosystem. The government’s SEMICON India programme includes a ₹76,000 crore PLI incentive, mostly committed to new factories. By late 2025, India approved 10 major semiconductor projects totaling ~$18.2 billion. For example, a new HCL-Foxconn plant ($435M) was approved in mid-2025 as the sixth fab under this scheme. Several more fabs and packaging units (by Tata Group, Micron, etc.) are underway. Overall, India’s chip initiatives aim to make the country a “global hub” for chip design and manufacturing.

Q: What trends are driving startup funding in India?

A: Indian startups are seeing robust activity in certain sectors. In H1 2025, startups raised ~$4.95B. E-commerce and fintech are top recipients (each ~$1B+), followed by enterprise software and deeptech. AI and deeptech startups are especially hot: in early 2025, generative AI companies raised a record ~$524–665M. Today there are 122 Indian unicorns (each valued >$1B) with over $115B raised in total. The focus is shifting towards profitability and sustainable growth, so startups with strong fundamentals (good unit economics) are attracting most investor attention.

Q: What is India’s rank in global innovation and patents?

A: India’s innovation rankings have improved markedly. In the 2024 Global Innovation Index, India is 39th globally, its highest position ever. India ranks 1st in its income group and region, reflecting strong performance in technology outputs. On intellectual property, India surged into the top 6 countries for patent applications, with 64,480 filings in 2023. Remarkably, 55% of those patents came from Indian residents (a first). The number of patents granted also rose by 149% in 2023, indicating the tech sector’s growing maturity.

Q: What government initiatives support India’s tech and startup ecosystem?

A: The Indian government runs several flagship programs: Digital India to build national digital infrastructure, Startup India to provide funding and regulatory ease for startups, and Make in India to boost manufacturing (including electronics). In 2024–25, the government launched the Research, Design & Innovation (RDI) Scheme with ₹1 lakh crore for strategic R&D, covering AI, semiconductors, and biotech. The new India Semiconductor Mission and PLI schemes incentivize chip fabs and design. Additionally, skill development initiatives (e.g., NASSCOM’s training programs, university partnerships) aim to cultivate tech talent. All these efforts create a supportive environment for innovators and investors alike.